- January 7th, 2014

- Comments Off on Our Cream Cheese – Handmade to Pair

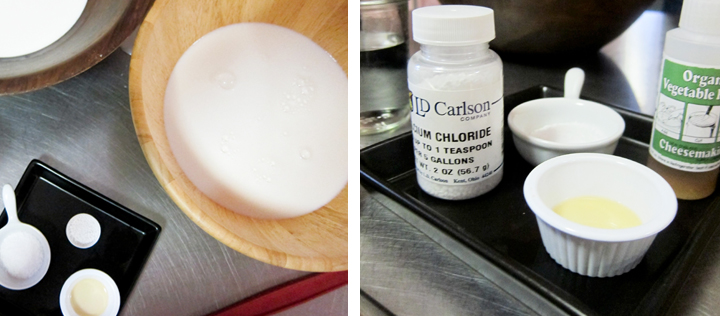

First we collect our ingredients, from the many forms of dairy to the enzymes that make cheese what it is.

The whole milk and half & half are mixed in a large stainless steel pot where calcium chloride – a salt solution that rebalances the calcium of pasteurized milk – is added with the diary. The pot is then heated to 70’F. We then add whey from the previous batch of cream cheese, used for acidity, and add the rennet. This process drops the pH and makes the curd. We then cover and allow the pot to coagulate for 24-36hrs.

After the rest, the curds are sprinkled with salt and cut. Cheesecloth is cut to the appropriate size and boiled to sanitize. We then line the drip container with the cheesecloth and strain the whey from the curds for 6-12hrs – all depending on the size of the batch and consistency of cream cheese we’re aiming for.

Now you know, with every dip, dunk or spread of cream cheese you have in-store comes from our kitchen and loads of love.